Manufacturing Industries should deliver competitively priced goods and services that satisfy human needs and bring quality of life, by finding progressively smarter and finer trade-offs between business and sustainability concerns.

Europe was the cradle of the manufacturing industry and it has traditionally led important industrial changes. Process industries represent the foremost part of the manufacturing base, around 20% of the total European manufacturing industry, which include more than 450,000 individual enterprises (EU27), employment of around 6.8 million citizens and generation of more than 1,600 billion € turnover. On other hand, process industries are largely dependent on resources imports from international markets that are hampering the industry’s access to globally traded raw materials, due to the increased political instability in many regions of the globe, which is perfectly visible from a sharp increase in raw material prices during recent years. Moreover, European industry has also accounted for more than a quarter of total energy consumption in 2010 in Europe1 with a significant portion of that used within the process industry.

This represents both an opportunity and responsibility of this sector contribution to the sustainability challenges of European societies, being imperative to drastically reduce the environmental footprint and increase competitiveness and production systems efficiency by “doing more with less”. However, to successfully implement sustainability in manufacturing and process industries, a holistic, multidimensional and systematic approach is required.

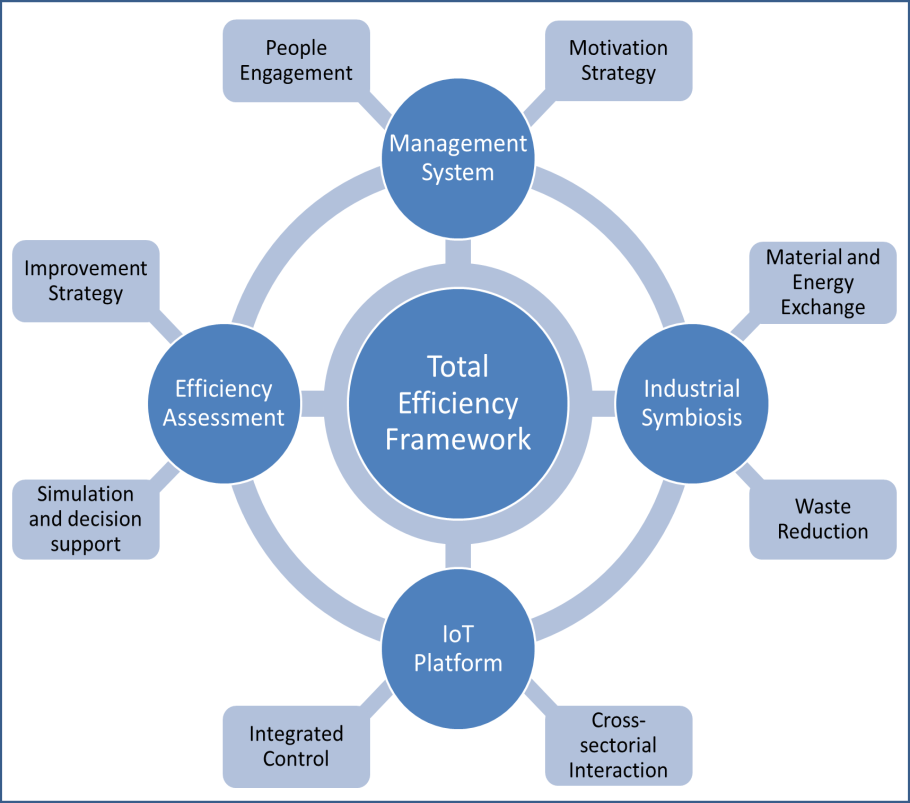

With this in mind, the MAESTRI project aims to advance the sustainability of European manufacturing and process industries by providing a management system in the form of a flexible and scalable platform to promote and simplify the implementation of an innovative approach, the Total Efficiency Framework. Based on a holistic approach which combines different assessment methods and tools, the overall purpose of the Framework is to generate improvement on a continuous basis and increase eco-competitiveness by fostering sustainability in routine operations.

Its conceptual approach will be based on a life cycle perspective, centered on models for dynamic simulation and optimization, of both individual and complex systems, to better understand processes and the opportunities to add value. This life cycle approach is important to avoid problems shifting from one life cycle stage to another.

We also believe that in order to develop more resource and energy efficient processes, utilize waste streams and improve recycling in a sustainable manner, modelling and assessing all the interacting value chains is essential. However, despite the environmental, economic and social improvement potentials by sharing resources (e.g. energy, water, residues and recycled materials), it is essential to understand and assess resource and energy efficiency in order to optimize production systems.

Moreover, the increased availability of ultra-modern technologies for process monitoring and optimization should be carefully adapted and integrated for a wider and facilitated adoption of state-of-the-art tools and methodology for efficiency and eco-efficiency. Such methodologies and tools should support wastes and cost reductions in to companies (large or small).